Ligonier Diamond Renaissance Project

The EADS Group was commissioned by The Borough of Ligonier to prepare the design of the Ligonier Diamond Renaissance Project. This project consisted of a thorough revitalization of the Heart of Ligonier’s Business District. The Diamond Park was originally laid out by founder, John Ramsay, in the early 1800’s as a corral for horses and wagons. In 1894 it was transformed into a park with a bandstand. The last significant improvements were completed in 1967. Ligonier Borough’s goals for this project were to redesign and reconstruct the Historic Park implementing modern technologies and features which will reduce maintenance costs, improve safety and reduce liability, and provide for enhanced enjoyment of the Borough’s residents and visitors over the next 50+ years.

The EADS Group was responsible for assistance with grant applications to private foundations, topographic surveys, preparation of renderings and master site plan, attendance at committee and council meetings, completion of preliminary design and cost estimates, completion of drainage and stormwater management improvements, preparation of PennDOT Highway Occupancy Permit and Building Permit, completion of final engineering, preparation of bid documents including drawings and specifications, assistance during bid phase, construction administration / management and full-time construction inspection.

This Project has won several awards including the ACEC/PA 2020 Special Projects Diamond Award, and it was designated in 2019 by the APA PA as one of three Great Public Spaces in Pennsylvania and the single Greatest Transformation of a Public Space.

![]()

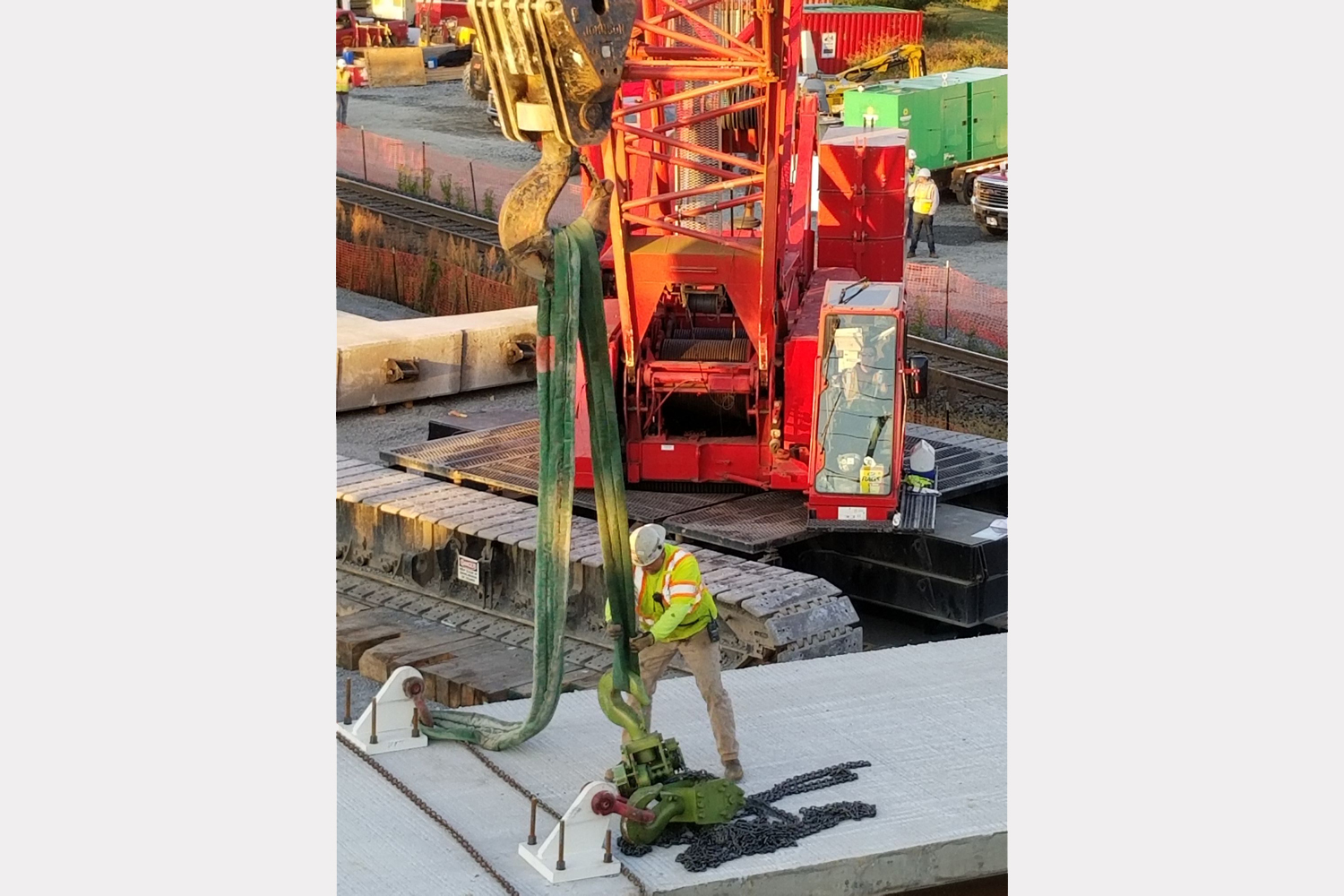

Pennsylvania Turnpike Bridge Replacement EB-117 at MP 238.09

The project consisted of the replacement of the existing Bridge EB-117 over the Norfolk Southern (NS) Railroad during the 2018/2019 Construction Seasons. The existing three-span steel girder bridge was replaced with a single span steel rolled girder bridge utilizing Accelerated Bridge Construction (ABC) Methods. In order to complete the EB-117 Bridge project, two separate weekend 59-hour road closures (Plan-X), one eastbound and one westbound along the Pennsylvania Turnpike were implemented. The traffic between the Gettysburg Pike Interchange (236) and the Harrisburg West Interchange (242) was detoured under weekend only detours.

The EADS Group was responsible for constructability review, construction inspection, construction management, schedule review, environmental oversight, utility coordination and project partnering.

This Project was awarded the Associated Pennsylvania Constructors TQI Partnering Award.

![]()

Lewistown Narrows

Previously, Lewistown Narrows (Route 22/322) was a two-lane highway capped on either end by four-lane interstate “look-alikes”. The result was a dangerous bottleneck with a high-profile crash history. To modernize the highway, the design team had to squeeze two additional lanes into the already tight Valley while remaining sensitive to the historic Pennsylvania Canal System and significant environmental concerns – all while keeping the roadway open to traffic throughout the massive year-round construction and keeping a close eye on the dangerously unstable mountainside. A bifurcated alignment was chosen for the narrowest portion of the roadway – pushing westbound lanes 20 feet above eastbound lanes for about 2.3 miles. Supporting the alignment is the longest mechanically stabilized earth wall in the U.S. Also supporting the alignment is a unique pin-pile system to stabilize the rocky mountainside. A Canal Park and off-site wildlife habitat were designed to mitigate any impacts of the reconstruction.

The EADS Group was responsible for the overall project management and agreement administration, wetland and stream mitigation, environmental assessments, surveys, highway and structures design, and construction consultation.

This Project has won several awards including the ACEC/PA Grand Conceptor Diamond Award, the ACEC Honor Award, FHWA Excellence in Highway Design Award, and the ARTBA-TDF GLOBE Award.

![]()

Omni Hotels & Resorts Bedford Springs Clubhouse

The new 4,500 SF Bedford Springs Clubhouse was designed replicating an original clubhouse facility previously located on the same site, maintaining the historic exterior context. The interior includes a new state-of-the-art restaurant, bar, kitchen, restrooms, locker rooms, and Golf ProShop. Outdoor dining areas and golf cart landing areas were also provided.

The EADS Group, Inc. completed the architectural, site, civil, structural, electrical, mechanical, plumbing and interior designs and provided ADA code review services. An aggressive schedule was maintained throughout the design and construction phase in order to meet the client’s deadlines for this $2.6 million project.

Photo Credits: Dave Hammaker Photography

![]()

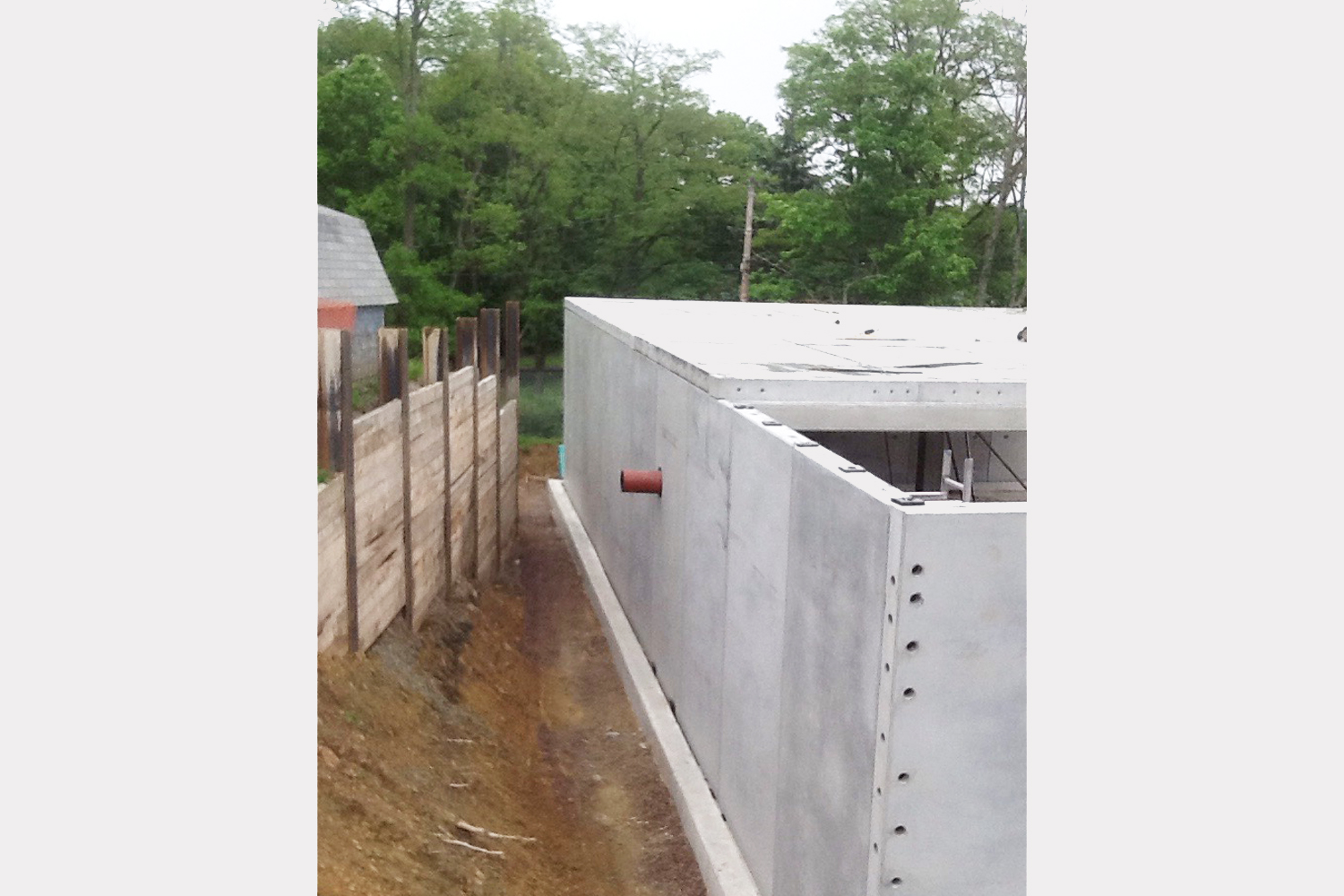

Mechanic Street Relief Sewer Improvements

The LaVale Sanitary Commission engaged The EADS Group, Inc. to perform engineering services for the replacement of the above ground portion of their 24” diameter force main. The existing force main conveyed wastewater from the LaVale area, City of Frostburg and portions of Allegeny County, MD. The existing force main was constructed of PCCP and both the exterior concrete layer and reinforcing wire had failed in areas. The design process included detailed coordination due to the existing force main location between an active railroad and a floodwall. The design included bypassing arrangements using hot taps and line stops to provide continuous service during construction. The existing force main was replaced with 24” ductile iron restrained joint pipe with expansion joints. Extensive concrete repairs to areas of the support wall were also included in the project.

The EADS Group, Inc. prepared the funding application, all permit applications, and performed design, bidding and construction administration services for the $1.46 million project.

![]()

Trolleyworks Business Park

In a city with a history as rich as Altoona’s, local businesses generally appreciate a savvy juxtaposition of historic architecture and modern amenities. With this in mind, the Trolleyworks Business Park Renovation Project has taken a historic industrial building and repurposed it into a modern, energy-efficient business park. Highlights of the project include an industrial chic conference room with lighting designed to highlight the architectural features and produce a nighttime “glowing” effect, a unique spiraling courtyard, and a locally inspired mural in the conference room.

The EADS Group, Inc. was contracted to rehabilitate the existing 8,130 square feet trolley facility, providing the architectural components and overall site work for this $1.4 million project.

Photo Credits: Dave Hammaker Photography

![]()

Lake Stonycreek Sanitary Sewer

To address malfunctioning private on-lot septic systems at Lake Stonycreek, the Stonycreek Township Supervisors contracted The EADS Group to provide engineering services for the design of a new sanitary sewer collection system to serve Lake Stonycreek and adjacent areas. The role of The EADS Group began with completion of the Township-wide Act 537 Sewage Facilities Plan, followed by work with the Township to secure adequate funding for the project through the United States Department of Agriculture Rural Development Office. The design of the new facilities included 15,000 LF of 8” diameter to 12” diameter sanitary sewers, 47,600 LF of 1 ¼” diameter to 4” diameter pressure sewers and 229 new customer connections including 195 grinder pump units. Also included was the design of a 50,000 GPD expansion of the Shanksville Borough Sewage Treatment Plant, which is receiving and treating flow from the Lake Stonycreek project.

Unique considerations were necessary for this project due to environmental and archaeological features related to the site. Part of the constructed collection sewers area was populated by a protected plant species for which permitting, and construction considerations had to be implemented. This included obtaining a Wild Plant Permit and also an Individual NPDES Permit for Stormwater Discharge Associated with Construction Activities due to the protected plant species occurring adjacent to delineated wetland areas. Also, because a section of pressure sewer was installed as an aerial crossing on a bridge over the lake, a U.S. Army Corps of Engineers Section 404 Joint Permit was obtained to allow this construction. Regarding archaeological issues, findings from the Phase I Archaeological Survey necessitated the relocation of a portion of the sanitary sewers during design.

The EADS Group provided the funding application, all permit applications, and performed design, bidding and construction administration services for the $5.12 million project.

![]()

Logan Town Center Site Development

The EADS Group assisted the owner in developing the site plans, (conceptual, preliminary and final plans) for the Logan Town Center, a 320-acre, 850,000 sq. ft. power retail center. The property is located between the 17th Street and Frankstown Road, I-99 interchanges, near Altoona, PA on the wooded slopes of Brush Mountain. The location provides direct access and visibility to I-99, and the Blair County regional population base.

The development of the site included facility layout and parking for all tenants, on and off site roadway design for state and township roads providing adequate traffic access, electric and gas line relocation, and utility coordination and design. This project required extensive project management and coordination between the engineer, developer, governmental agencies (i.e., obtaining the waterways, environmental & sedimentation, and building permits), local township engineer, PennDOT and planning commissions. Unique to this project was environmental concerns involving significant permitting and wetland mitigation issues, which required many field and office coordination meetings with the natural resource agencies, environmental assessments, and stream mitigation. A total of 163-acres of the 320-acre site were disturbed, with 56 wetlands (4.65-acres) identified and over 2,000,000 C.Y. of earth moved. A Wetland Mitigation Plan was developed and approved by the permitting agencies. A NPDES Phase II permit was applied for and obtained by EADS. E&S and stormwater BMP’s were utilized.

Mead Avenue Bridge

Mead Avenue is one of the three major east-west routes carrying traffic across French Creek and provides the most direct route into downtown Meadville from the west. The City of Meadville wanted to promote Mead Avenue as a gateway into the city from the west; however, the Mead Avenue Bridge had fallen into disrepair. After 136 years of use, the bridge had deteriorated to a condition it could no longer be effectively maintained. Replacement of the bridge presented many obstacles and challenges to overcome, including the potential for environmental impacts to aquatic life in French Creek, historical significance of the bridge, site constraints due to the proximity to Bicentennial Park and the intersection with SR 0102 (Cussewago Road), and the existing bridge crossing on French Creek is considered obstructive to major flood flows.

The EADS Group design team delivered a bridge project that improved the efficiency, capacity and safety along a portion of Mead Avenue; has the potential to alleviate traffic from other parallel roads that are deficient in their level of service; maintains or improves access to the Industrial Park; sustains local businesses and industry; supports and expands regional and local economic development needs and was detailed to be aesthetically appropriate for the setting. The overall project cost was $11 million.

![]()

Lower Yoder Sanitary / Storm Sewer Separation

The Lower Yoder Township sewer system serves approximately 1,230 residential customers and 83 commercial customers for a total of 1,313 customers. The system consists of approximately 95,000 linear feet of 8” gravity sewer collection lines, 25,000 linear feet of 10”, 12”, and 15” gravity sewer interceptor lines, and 640 manholes. The Westmont and Brownstown sewer systems also flow through Lower Yoder Township’s sewer system. The wastewater from the Lower Yoder Township sewer system is discharged to the Johnstown Redevelopment Authority (JRA) owner and operated interceptor sewer with ultimate treatment at the Dornick Point Treatment Plant which is also owned and operated by JRA.

Initially, The EADS Group, Inc. provided a feasibility analysis that determined that excessive sanitary sewer flows caused by inflow and infiltration (I/I) have been contributing to SSO activity both in the Township and downstream of the Township in the City of Johnstown. It was determined that the best course of action to eliminate Lower Yoder’s contribution to SSO activity was to replace all of the existing terra cotta and transit lines and brick manholes. The replacement of these lines will be completed in 3 phases of construction all designed and managed by EADS.

The EADS Group provided the funding application; all permit applications; and performed design, bidding and construction administration services for the $22 million project.

Grit Removal Unit And Automatic Bar Screen Construction

Windber Area Authority contracted The EADS Group to provide engineering services for the design of a grit removal unit and automatic bar screen at the head works of the Ingleside SBR sewage treatment plant. The Authority’s existing horizontal flow chain and bucket grit removal system were due for replacement, and rags/wipes in the influent flow were causing operational problems in the treatment process. In order to update the grit removal unit and alleviate the existing problems, EADS designed a vortex Pista Grit installation featuring a cast in place concrete grit chamber with grit pump, grit separator and a conveyor system to handle 10 MGD of sewage flow. The automatic bar screen unit is mounted in a cast in place concrete channel inside the existing grit handling building to effectively remove rags/wipes and other inorganic material upstream of the new grit removal unit.

The EADS Group, Inc. completed the study and report of equipment/installation options, surveys, design plans, all permitting applications, bidding, construction administration services and startup assistance.

Hickory Hill Tank Replacement

The Municipal Authority of the Borough of Somerset decided to replace their 1 MG 70-year old cast-in-place potable water tank. The proposed replacement tank was designed to occupy the same footprint as the existing water tank due to system hydraulics, available area and existing utility and communication facilities.

The EADS Group, Inc. prepared the funding application, all permit applications, design, bidding and construction administrative services for the $1.806 million project.

A precast post-tensioned concrete tank system was selected for this project to minimize impacts to the Authority’s water system and the surrounding residential area. The walls of two 0.5 MG pre-cast post-tensioned water tanks were exposed during construction. These tanks were constructed in 1995 and appeared to be in excellent condition.

Flight 93 National Memorial Site Development & Roadway Design

The EADS Group has played an important role in the development of the National Park Service’s Flight 93 National Memorial. EADS prepared the site civil plans for the 330-acre Memorial area. This includes the contour grading, layout & dimensioning, overall horizontal and vertical control for the ring road, pedestrian walkway and sacred ground plaza, site drainage design and the surveying and mapping for the Memorial. EADS prepared the NPDES Permit, which included the Erosion and Sediment Pollution Control Plan and Post Construction Stormwater Management Plan, the Corps Section 404 Permit and the PADEP 401 Water Quality Certification. A stream wetland mitigation plan was prepared mitigating impacts to Exceptional Value waters and wetlands.

EADS also provided design and permitting of the water and sewage facilities that serve the Memorial. This required the preparation of feasibility studies and a planning module and subsequently undertaking the design of these facilities. As a companion project to the Memorial, EADS designed and permitted the primary entrance road that provides access to the Memorial. The project was constructed, on schedule, for September 11, 2011.

Stonycreek Township Sanitary Sewer Rehabilitation

The Johnstown Redevelopment Authority (JRA) entered into a Consent Order and Agreement (COA) with the Pennsylvania Department of Environmental Protection (DEP) due to recurring instances of overflow of the sanitary sewer system owned and operated under its jurisdiction. Stonycreek Township contributes sanitary sewer flows to JRA and therefore was included in the COA. The COA required a reduction of sanitary sewer flows to a design rate per household as designated by DEP. Excessive sanitary sewer flows were directly related to groundwater inflow and infiltration of the aged and deteriorated infrastructure of the contributing sanitary sewer systems.

Stonycreek Township contracted The EADS Group, Inc. (EADS) to provide engineering and related services for the rehabilitation of their sanitary sewer system. The design completed by EADS included slip-lining or pipe-bursting of 92,000 LF of 8”, 10” and 12” diameter sewers, replacement of 430 sanitary sewer manholes, and installation of 1,200 customer service laterals from the sanitary sewer main to the property right-of-way line. For this fully funded $13 million project, EADS assisted the Township with funding applications and administration.

The completed project resulted in a 40% total average reduction of sanitary sewer flows. The project was completed on schedule and $1.2 million under budget.

Tioga County Department Of Emergency Services And 911 Center

The Tioga County Department of Emergency Services and 911 Center were housed in a facility that did not meet the current or future needs for proper emergency response operation. Working within an existing County-owned building, The EADS Group coordinated the programmatic needs of Tioga County into a modern technologically advanced facility. The new facility provides the latest advances in emergency response technology and provides the required areas for a fully functional 911 facility. The project also included a new 4,200 SF HAZMAT response vehicle and materials storage garage.

EADS responsibilities for this $5.2 million project included space needs assessment, preliminary and final design, opinion of construction costs, construction drawings and specifications, assistance with bidding and award of construction contracts, coordination with telecommunications and security consultant, coordination with advanced security door hardware consultant, and construction phase project representation services.

Antietam Wastewater Treatment Plant Upgrades

Washington County, Maryland contracted The EADS Group to provide design services for upgrades to the Antietam Wastewater Treatment Plant. The Wastewater Treatment Plant project involved the replacement of the Headworks Building, the existing building and equipment were severely corroded due to high hydrogen sulfide levels. Upgrades included the removal of existing building and corroded equipment, repair of concrete flow channels, and construction of an open air pavilion structure. Improvements to the Pre-Aeration Facility were included in order to reinstate pre-aeration into the process to increase dissolved oxygen levels prior to treatment in the oxidation ditches. Due to the age of the system, the ultraviolet disinfection system was replaced to meet today’s advanced technologies. The oxidation ditch drive units were also replaced. The existing underground storage tank system was removed and replaced with an above ground system to serve the boiler and emergency generator. Miscellaneous upgrades to the existing plant piping, instrumentation interconnections, valves and site work were also included with this project.

The EADS Group, Inc. provided surveying, design plans and specifications, and engineering support for construction.

City of Cumberland Sodium Hypochlorite Conversion

The EADS Group, Inc. was contracted by the City of Cumberland to complete a study to evaluate the costs associated with converting the existing gaseous chlorine system at their Lake Gordon Water Treatment Plant to a liquid sodium hypochlorite system. The study evaluated three options to provide chlorine to the treatment process using the existing one-ton chlorine cylinders, a combination of 150-pound chlorine cylinders in combination with liquid sodium hypochlorite, and the complete conversion to liquid sodium hypochlorite.

Following the City’s authorization, The EADS Group preceded with the design and permitting to completely convert the chlorination facilities to utilize only liquid sodium hypochlorite. The full liquid sodium hypochlorite system was designed including approximately 18,000 gallons of bulk storage, one chemical transfer pump, a 500-gallon day tank, pre-chlorination feed pump facilities, post chlorination feed pump facilities, controls, and all associated appurtenances. EADS also completed permitting applications, bidding, and construction administration services.

Hickory Street Bridge Inspection

The EADS Group has extensive knowledge regarding the National Bridge Inspection Standards (NBIS) and has been working in the program since the early 1980’s. EADS currently serves clients across the state to meet the compliance needs of the NBIS Program. This currently includes over 400 bridges in Western and Central Pennsylvania. The photos below are from a recent inspection of the Hickory Street Bridge in Johnstown, PA for PennDOT District 9-0 in Hollidaysburg, PA.

Photo Credits: Dave Hammaker Photography

Lavale / Braddock Run Interceptor Sewer Rehabilitation

The LaVale Sanitary Commission’s main interceptor sewer was constructed in the mid-1960’s and was subject to infiltration and inflow during precipitation events and high ground water conditions. The EADS Group, Inc. was contracted to provide design bidding, construction inspection, and funding services for Phases I & II for the rehabilitation of the interceptor sewer. The Commission selected trenchless technologies including cured-in-place piping, lateral grouting and multi layer manhole rehabilitation to rehabilitate the interceptor. Trenchless technologies provided an advantage by reducing the disruption to existing commercial and residential customers adjacent to the interceptor sewer. A total of 11,450 feet of 16” and 18” interceptor sewer and 62 manholes were included in Phase I of the project.

Phase II of the project included the rehabilitation of 12,610 feet of 16”, 18”, and 24” interceptor sewer and 58 manholes. Phase II construction began July 1, 2011, and was completed in October 2012.

The EADS Group prepared the funding application, all permit applications, design, bidding and construction administrative services for Phase I and II of this project. The Commission obtained grant funding of $2.45M from the Maryland Department of the Environment to completely fund both phases of the project.

Roaring Fork Superstructure Replacement

The EADS Group, Inc. provided engineering and related services for a superstructure replacement and substructure modifications to the Roaring Fork Bridge which carries T-816 over Roaring Fork in Ogle Township, Somerset County. It was estimated that the bridge was built in 1940 and was determined to be in serious condition due to numerous corrosion holes in the steel beams.

Work included the replacement of the existing steel I-beam superstructure and timber deck with a new galvanized steel I-beam superstructure and reinforced concrete deck. The overall length of the new structure is 33.5 feet. The existing stone masonry substructures were re-used. However, the tops of the abutments and wings were removed and new concrete caps were poured on top of the portions that remained to accommodate the new superstructure geometry. The project was funded with 80% federal funds and 20% state funds.

EADS provided surveys, mapping, structural and roadway design, utility coordination, environmental clearances, assistance with obtaining PADEP Permit, bidding and award, and construction consultation.

SR 219, Section 020 – Meyersdale To Somerset Environmental And Construction Inspection

This three phased $250 million project consisted of a new 11-mile stretch of roadway on SR 219 in Somerset County. The first phase required moving 11 million cubic yards of earth and installing drainage in the project area. The second phase consisted of the construction of six (6) bridges, and the third phase was the actual roadway paving.

For this mammoth project, a portion of the construction inspection and all environmental services were provided by The EADS Group. As part of the environmental services, EADS provided monitoring oversight of all wetland and stream impacts, relocations, and mitigation areas. EADS also provided real time water quality information to the various state and federal regulatory agencies as per the Compensatory Mitigation Plan and Permit special conditions and conducted macroinvertebrate sampling of various watercourses.

Unique to this project was a missing mile of earthwork that had to be specially treated since a mining company was given permission to continue coal mining operations. This area required a treatment called deep dynamic compaction to prepare the subgrade for the road pavement. Deep dynamic compaction is a ground improvement technique that densifies soils and fills by using a drop weight lifted by crane and repeatedly forced on the ground surface.

Also specific to this project was the construction of Buffalo Creek Bridge with a span over 1100’ and 220’ height clearance, which is the longest and highest of the six bridges constructed at the site.